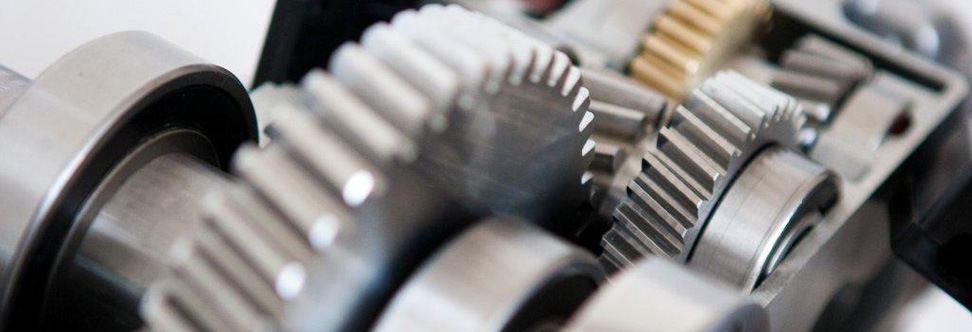

EXACTING PRECISION MECHANICS

All mechanical components, gears, housings, every single part of the motor and relevant windings are manufactured entirely in-house here in Italy.

Roger Brushless technology's excellent mechanics are based on the traditional design and construction principles of classical mechanics, using skilfully crafted components designed and built to last.

When it comes to mechanics, we are steered by our philosophy to use strictly metal of either the ferrous or non-ferrous variety, such as: aluminium used for automation device housings; carbon alloy steels for gears, which often undergo heat treatment for superior hardness; aluminium bushings for gears that work in conjunction with worm screws, which are also made from steel.

Everything is designed to produce automation systems that are built to last.

Main features of the excellent mechanical parts made by Roger Technology in terms of quality and manufacturing processes.

- Casings, housings and profiles made from titanium-reinforced die-cast aluminium

- All mechanical parts made using top-quality materials, such as aluminium, steel, cast iron and bronze

- Seats machined to avoid vibrations

- Gears assembled with high-quality double-shielded ball bearings

- Bearings inserted in accurate seats re-machined to ensure absolute precision between gear shafts

- Worm screws and motor shafts are rolled to avoid porosity and achieve very strong mirror-finish surfaces

- Task-specific industrial greases and lubricants used to extend the service life of kinematic mechanisms

- Inspection, testing and assembly carried out with the utmost care and devotion

Nederland

Nederland Italiano

Italiano Français

Français Deutsch

Deutsch Belgium

Belgium Português

Português Español

Español Polski

Polski